Hägglunds Torque Arm Drive System - TADS, Hydraulic direct drive system

Description

Reviews

Download:

Data Sheet of Hägglunds Torque Arm Drive System

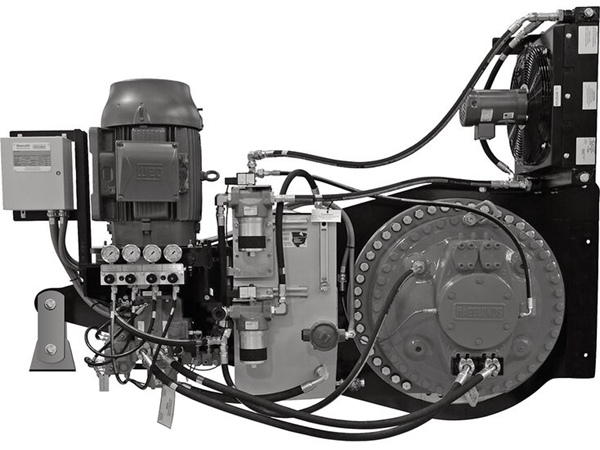

Hägglunds Torque Arm Drive System - TADS, Hydraulic direct drive system

Bosch Rexroth has released the TADS Hagglunds torque arm drive system, which removes the gearbox and heavy base, reducing installation costs and saving valuable space. H ä gglunds TADS is a completely independent and easy to install hydraulic system equipped with internal splines or hollow output shafts with compression coupling, which can be easily installed directly on the machine's drive shaft. Flexible couplings and related alignment issues, excessively long hoses or lines, and control lines between conventional power units and clicks have been eliminated. TADS is a hydraulic drive system that can be used for limited space applications.

TADS provides maximum torque from zero speed, with unlimited start, stop, and flip, without damaging the system. This feature can add new productivity to certain applications, especially plate feeders, belt feeders, belt conveyors, recycling, cement, pulp, and paper industries in bulk material processing and mining.

The Hagglunds TADS unit is equipped with an extremely fast hydraulic pump compensator, which can reduce wear and prolong the lifespan of the machine. Load sensing and power limiting tools can enable operators to intelligently maintain peak operating levels, outperforming other systems, improving machine uptime and helping to reduce total cost of ownership.

The HAGGLUNDS TADS hydraulic drive system has the following obvious advantages over traditional mechanical methods: stepless speed regulation, fast and frequent start and stop, and low impact on the power grid; High starting torque, strong starting ability, and strong overload resistance; The equipment has reliable quality, long service life, low failure rate, small maintenance volume, and low maintenance costs; Easy to install and operate; Energy conservation and environmental protection.

General info

- Torque: Up to 275231.04 Nm;

- Speed: Up to 60 rpm;

- Max. operating pressure: 349.98 bar;

- Power: Up to 74.57 kW;

- Ambient temperature -40 … +40.56 °C.

Features

- Designed for apron feeders, belt feeders, belt conveyors, and infeed conveyors

- Small footprint

- Self-contained drive system

- Easy installation

- Maintenance friendly design

- Spline or Shrink Disc Motor

- Hägglunds advanced control system

- No foundation needed

- Unlimited starts and stops

- Direct drive